A research team led by Professor Jinho Chang from the Department of Electrical Engineering and Computer Science at DGIST has developed an “ultrasound-based wireless charging technology” capable of rapidly and efficiently charging the batteries of implantable medical devices. This technology has achieved world-class energy efficiency, fully charging a commercial battery within two hours, even inside the human body.

The research is published in the journal Biosensors and Bioelectronics.

Recently, due to population aging, diseases, and accidents, a rapid increase in demand for implantable medical devices (e.g., pacemakers and neural stimulators) has been observed. However, the batteries in these devices must be replaced periodically, requiring patients to undergo repeated surgeries—posing both inconveniences and risks. To address this issue, developing technology that can wirelessly transmit energy from outside the body is essential in order to charge the batteries without the need for additional surgeries.

Although wireless charging technologies using ultrasound have existed previously, harvesters (energy receivers) that can be implanted in the human body have faced limitations in size and structure. Additionally, the ultrasound intensity that can be safely used in the human body is restricted, resulting in insufficient power output.

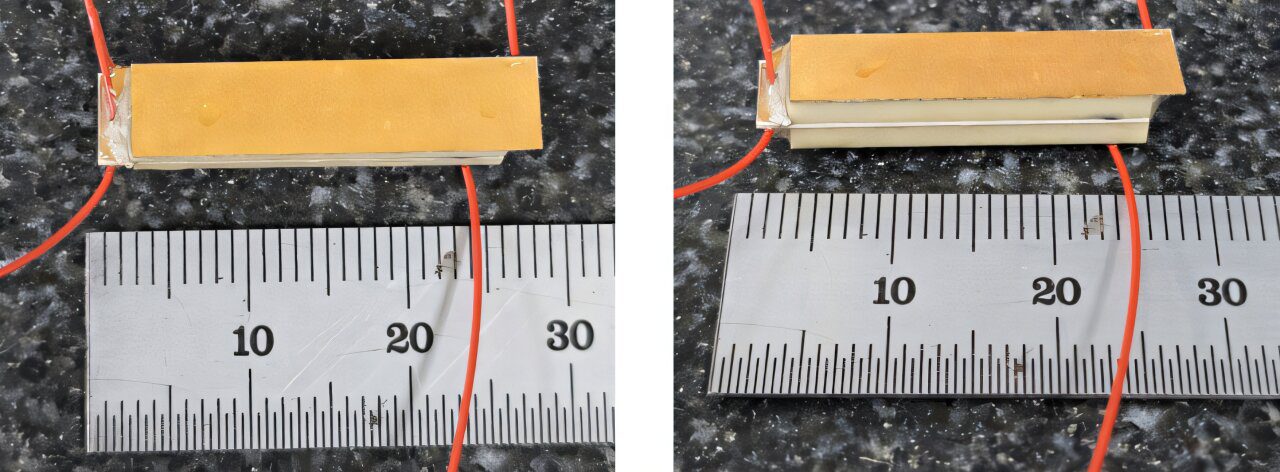

To overcome these limitations, Professor Chang’s research team at DGIST developed a new type of “sandwich-structured piezoelectric energy harvester.” Two piezoelectric layers are stacked such that the front layer harvests incoming ultrasound energy to generate electricity, while the rear layer captures the residual ultrasound to produce additional power. By combining the output from both layers, the harvester achieves over 20% greater efficiency compared to that of conventional designs.

Using this technology, the research team demonstrated that a 140mAh commercial battery could be fully charged in just one hour and 40 minutes at an…

Disclaimer

We strive to uphold the highest ethical standards in all of our reporting and coverage. We 5guruayurveda.com want to be transparent with our readers about any potential conflicts of interest that may arise in our work. It’s possible that some of the investors we feature may have connections to other businesses, including competitors or companies we write about. However, we want to assure our readers that this will not have any impact on the integrity or impartiality of our reporting. We are committed to delivering accurate, unbiased news and information to our audience, and we will continue to uphold our ethics and principles in all of our work. Thank you for your trust and support.

Website Upgradation is going on. For any glitch kindly connect at 5guruayurveda.com